Hydrogen Sulfide (H2S) is a colorless, highly toxic gas that poses serious health risks when present in the environment. It is commonly found in industries such as oil and gas, wastewater treatment, and agriculture. Exposure to high concentrations of H2S can cause respiratory problems. , nausea, and even death. To mitigate these risks, the use of H2S gas detectors is critical. In this blog post, GasDog will dive into what Hydrogen Sulfide gas detectors are, how they work, why they are important, and the types available.

GasDog Hydrogen Sulfide gas detector is a device specially used to detect the presence of H2S gas in the air. These detectors are widely used in various industries to monitor environments where Hydrogen Sulfide may be present due to industrial processes or natural phenomena. By continuously monitoring H2S levels, these detectors provide early warning signs, enabling workers to evacuate or take appropriate safety measures promptly.

H2S Gas Detector Working Principle

There are different types of Hydrogen Sulfide gas detectors, but most operate based on one of several common principles:

- Electrochemical Sensors: These sensors utilize electrodes immersed in an electrolyte. When H2S gas contacts the electrodes, it triggers a chemical reaction that generates an electrical current proportional to the gas concentration. GasDog H2S detectors and monitors are based on electrochemical principles.

- Metal-Oxide Semiconductors (MOS): MOS sensors change their electrical conductivity in response to H2S gas. The presence of H2S alters the electrical properties of the sensor, which can be measured to determine gas concentration.

- Infrared Sensors: Infrared detectors use the absorption of specific wavelengths of infrared light by H2S molecules. By analyzing the amount of light absorbed, the sensor can quantify the gas concentration.

- Catalytic Bead Sensors: These sensors contain a catalyst that promotes the combustion of H2S gas. The heat generated by this reaction is measured and used to calculate gas concentration.

Types of Hydrogen Sulfide Gas Detectors

Portable Hydrogen Sulfide (H2S) Gas Detectors

Portable Hydrogen Sulfide (H2S) gas detectors are essential safety devices designed to protect individuals from the hazards of Hydrogen Sulfide exposure. These compact, lightweight detectors are easy to carry and use, making them ideal for a variety of industrial and field applications. Equipped with advanced sensor technologies, they provide real-time monitoring of H2S levels, ensuring immediate detection of dangerous concentrations. Features often include audible, visual, and vibrating alarms to alert users promptly, even in noisy environments. With fast response times and high sensitivity, portable H2S gas detectors are crucial for maintaining safety standards and preventing harmful exposure in dynamic and potentially hazardous settings.

Portable Hydrogen Sulfide (H2S) gas detectors are essential safety devices designed to protect individuals from the hazards of Hydrogen Sulfide exposure. These compact, lightweight detectors are easy to carry and use, making them ideal for a variety of industrial and field applications. Equipped with advanced sensor technologies, they provide real-time monitoring of H2S levels, ensuring immediate detection of dangerous concentrations. Features often include audible, visual, and vibrating alarms to alert users promptly, even in noisy environments. With fast response times and high sensitivity, portable H2S gas detectors are crucial for maintaining safety standards and preventing harmful exposure in dynamic and potentially hazardous settings.

Fixed Hydrogen Sulfide (H2S) Gas Detectors

Fixed Hydrogen Sulfide (H2S) gas detectors are used for continuous monitoring of H2S levels in industrial and commercial environments. These detectors are permanently installed in key areas where Hydrogen Sulfide emissions are likely, such as refineries, wastewater treatment plants, and chemical processing facilities. Equipped with advanced sensor technology, fixed H2S detectors provide accurate, real-time data on gas concentrations, ensuring immediate detection of dangerous levels. They feature robust alarm systems, including audible, visual, and remote notifications, to alert personnel promptly and facilitate swift action. GasDog can also provide professional industrial Hydrogen Sulfide gas detectors.

Fixed Hydrogen Sulfide (H2S) gas detectors are used for continuous monitoring of H2S levels in industrial and commercial environments. These detectors are permanently installed in key areas where Hydrogen Sulfide emissions are likely, such as refineries, wastewater treatment plants, and chemical processing facilities. Equipped with advanced sensor technology, fixed H2S detectors provide accurate, real-time data on gas concentrations, ensuring immediate detection of dangerous levels. They feature robust alarm systems, including audible, visual, and remote notifications, to alert personnel promptly and facilitate swift action. GasDog can also provide professional industrial Hydrogen Sulfide gas detectors.

What is Hydrogen Sulfide Gas Detector Used for?

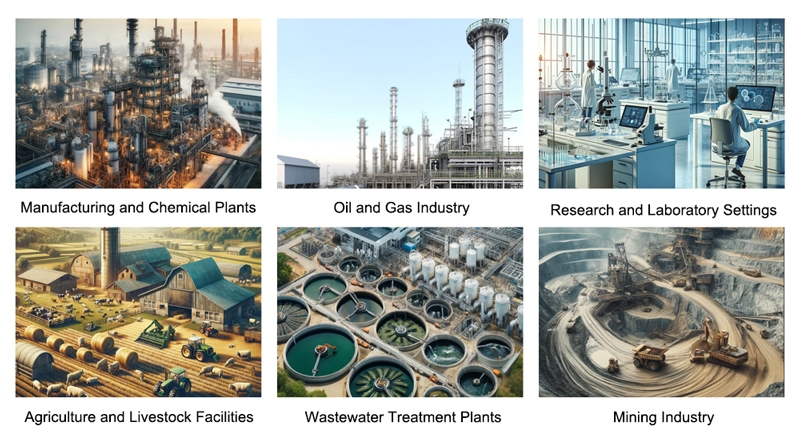

Hydrogen Sulfide (H2S) gas detectors play a vital role in various industries and settings where the presence of this toxic gas poses health and safety risks. The ability to accurately monitor H2S levels ensures early detection of potential hazards, allowing for timely interventions to protect workers and the environment. Here are some key applications of Hydrogen Sulfide gas detectors:

Oil and Gas Industry

In the oil and gas sector, H2S is commonly encountered during drilling, refining, and production processes. Gas detectors are used to monitor H2S levels in oil wells, refineries, pipelines, and storage facilities. Continuous monitoring helps prevent exposure incidents and enables prompt evacuation or shutdown procedures in case of leaks or releases.

Wastewater Treatment Plants

Hydrogen Sulfide can be generated during the decomposition of organic matter in wastewater treatment plants. Industrial gas detectors are employed to monitor H2S levels in sewer systems, pump stations, and treatment facilities. Early detection of elevated H2S concentrations helps protect workers and prevent corrosion of infrastructure.

Agriculture and Livestock Facilities

H2S can be produced in agricultural settings from manure decomposition, particularly in confined spaces such as barns or silos. Gas detectors are used to monitor H2S levels in livestock housing areas to ensure worker safety and prevent harmful exposure to animals.

Mining Industry

In mining operations, Hydrogen Sulfide can be released from underground mining activities, especially in coal mines and metal mines. Gas detectors are essential for monitoring air quality in mine shafts and tunnels to protect miners from the dangers of H2S exposure.

Manufacturing and Chemical Plants

Chemical manufacturing facilities and industrial plants where sulfur-containing compounds are processed or handled may encounter H2S emissions. Gas detectors are used to monitor indoor air quality and detect leaks or emissions that could pose health risks to workers.

Environmental Monitoring

Gas detectors are deployed in environmental monitoring programs to assess air quality and detect H2S emissions in areas near industrial sites or natural sources of Hydrogen Sulfide. This data is used to evaluate potential impacts on local ecosystems and public health.

Research and Laboratory Settings

In research laboratories, Hydrogen Sulfide gas detectors are used to ensure the safe handling of chemicals and prevent accidental exposure during experiments involving sulfur-containing compounds.

How to Choose the Right H2S Gas Detector?

When selecting a Hydrogen Sulfide gas monitor, several factors should be considered to ensure its effectiveness and suitability for the intended application:

- Detection Range and Sensitivity: Ensure that the detector's detection range and sensitivity align with the expected concentrations of H2S in your environment. Some detectors are designed for low-level monitoring, while others can detect the high concentrations typically found in industrial settings. The GasDog Hydrogen Sulfide gas detector can measure concentrations from 0 to 2000 ppm with an accuracy of up to 0.001 ppm, making it an excellent tool for precise gas detection.

- Response Time: The response time of the detector is crucial, especially in fast-changing environments. Faster response times allow for quicker detection of H2S leaks or spikes in concentration, enabling swift action to protect personnel. ≤10s is the response of GasDog gas detector time.

- Accuracy and Calibration: Regular calibration is essential to maintain the accuracy of Hydrogen Sulfide gas detectors. Choose a detector that is easy to calibrate and verify to ensure reliable performance over time.

- Durability and Environmental Conditions: Consider the operating environment where the detector will be used. Ensure that the detector is durable enough to withstand harsh conditions such as temperature extremes, humidity, and exposure to chemicals.

- Alarm System: Seek detectors that provide audible, visual, and/or vibrating alarms to alert users when H2S levels exceed safe limits. Ensure the alarm is loud enough to be heard in noisy environments and easily recognizable for a timely response. GasDog gas detectors and monitors feature highly sensitive alarms.

- Battery Life and Maintenance: For portable detectors, battery life is critical. Choose a detector with long battery life or the ability to recharge easily. Additionally, consider maintenance requirements such as sensor replacement and general upkeep.

- Integration with Safety Systems: If deploying fixed gas detectors, ensure compatibility with existing safety systems such as alarms, ventilation controls, or emergency shutdown mechanisms. Integration facilitates a comprehensive safety strategy.

- Regulatory Compliance: Verify that the Hydrogen Sulfide gas detector meets relevant safety standards and regulations applicable to your industry or region. Compliance ensures that the detector performs reliably and accurately under specified conditions.

To summarize, Hydrogen Sulfide gas detectors play a critical role in safeguarding workers and the public from the dangers of H2S exposure. By employing advanced sensor technologies, our GasDog detectors provide accurate and reliable monitoring of gas levels, enabling proactive safety measures and emergency responses when needed. As industries continue to prioritize worker safety and environmental protection, Hydrogen Sulfide gas detectors will remain indispensable tools in maintaining occupational health and safety standards.