GasDog Gas Detection Case Studies

Cl2 Gas Detector

C2H4 Gas Detector

CH2O Gas Detector

H2 Gas Detector

H2S Gas Detector

HCN Gas Detector

N2 Gas Detector

O2 Gas Detector

O3 Gas Detector

SO2 Gas Detector

1. Chlorine Detection in R&D of Special Gas Products

Background: A company engaged in the research, development, and production of electronic specialty gas products provides gases and related services for high-tech industries such as semiconductors, displays, optical fibers, and solar energy. One of the gases produced is Chlorine (Cl2), which is a yellow-green, toxic gas with a strong pungent odor under normal temperature and pressure. According to the workplace air hygiene standard, the Maximum Allowable Concentration (MAC) for Chlorine is 1 mg/m³. The Chlorine gas is filled into cylinders and stored in a dedicated storage room. To ensure workplace safety, personnel need a portable instrument to detect any gas leaks before entering the storage area. Additionally, it is necessary to continuously monitor the concentration of Chlorine gas in the production workshop. In the event of a leak, immediate ventilation is required, and the source of the leak must be quickly located to prevent harm to staff and equipment.

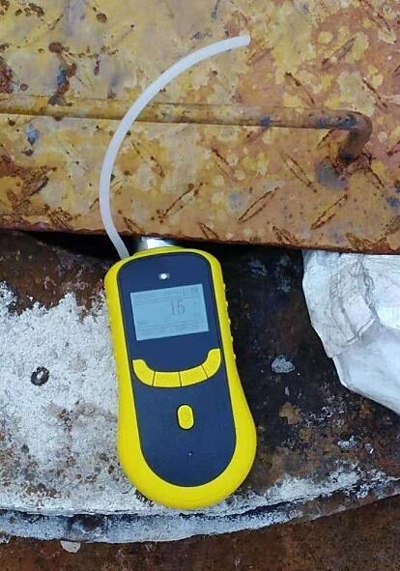

Solutions: To meet the user's safety and operational requirements, we recommend the GD200-Cl2 portable gas detector. This is a pump-suction type detector, which provides a faster response time and allows detection of Chlorine gas from a longer distance compared to diffusion-type detectors. This enhances safety by enabling users to assess air quality before entering potentially contaminated areas. The pump-suction feature is especially useful for pre-entry checks in enclosed spaces and enables early detection, thus helping to avoid exposure to toxic gas. Its high sensitivity and real-time readings support routine workshop concentration monitoring, while its portability ensures rapid deployment in emergency leak situations. After evaluating the options, the user selected and purchased the GD200-Cl2 portable gas detector, aligning with their safety protocols and operational needs.

2. GD200-C2H4 Gas Detector for University Experimental Research

Background: Ethylene exists in small amounts in plants and is a natural metabolite. It is a colorless and flammable gas that can slow down plant growth and promote leaf fall and fruit ripening. James, a graduate student at the university, contacted us to accurately detect the concentration of C2H4 during an experiment to control its progress. The goal was to measure the Ethylene concentration produced by peaches in a sealed experimental container.

The detection range requirements were carefully confirmed multiple times, and after final approval by the supervising professor, we provided the confirmed parameters. The experimental container was very small, with dimensions of only 20×15×30 cm (about the size of a lunch box), which posed a challenge for accurate gas measurement.

Solutions: Due to the small volume of the container, Gas Dog team proposed a needle hose loop detection method. This technique allows the gas to enter the instrument's gas chamber and then return to the experimental container, enabling accurate and stable detection of C2H4 concentration. Without this closed-loop method, the gas would be depleted too quickly during testing, leading to unstable and unreliable data. James and his professor were very satisfied with this solution and selected GasDog C2H4 single gas detector for their experiment. They later recommended GasDog gas detectors to other university laboratories for detecting Ammonia, Chlorine, and exhaust gas, highlighting the product's reliability and suitability for laboratory applications.

3. Testing Formaldehyde Removal with GD200-CH2O Detector

Background: The manager of Environmental Protection Intelligent Wall Materials Company contacted GasDog to conduct pre-production testing to verify whether their newly developed Formaldehyde-removing paint meets industry standards. As part of the experiment, they planned to place a CH2O stick into a sealed bottle and use a gas detector to measure the initial concentration of CH2O, which was expected to be around 0.25 ppm. After this baseline measurement, they would apply the Formaldehyde-removing paint into the bottle and reinsert the gas detector. Over time, the concentration of Formaldehyde inside the bottle would be observed to see if it gradually decreases, indicating the paint's effectiveness in removing CH2O.

Solutions: Considering the customer's experimental needs and the special properties of CH2O gas, we recommended our CH2O pump-type Formaldehyde detector, which is capable of accurately measuring CH2O concentrations in the range of 0–5 ppm.

We provided operational guidance for accurate results:

- The detector must be turned on in clean air to ensure baseline calibration.

- After testing, it is important to wait until the reading returns to 0 before turning the device off.

This is crucial because Formaldehyde has strong adsorption properties, and shutting off the detector while it still reads a concentration may cause gas residues to remain inside the instrument, leading to inaccurate readings in future tests. The manager appreciated the professional support and expertise provided by the Gas Dog team and expressed confidence in the solution.

4. Hydrogen Leak Detection in Glass Production

Background: A glass manufacturing company specializes in the production of architectural glass, automotive glass, decorative glass, fiberglass, glass containers and tableware, as well as processed glass with offline coating. During the processing and production of these glass products, toxic and hazardous gases such as Ammonia (NH3) and Hydrogen (H2) are often involved.

To ensure safety and environmental compliance, the company decided to implement a gas leak detection system to monitor and prevent the leakage of these harmful gases. Their objective was to protect worker safety, prevent fire hazards, enhance emergency response capabilities, and strengthen the company’s public safety image.

Solutions: To meet these safety requirements, the company purchased hundreds of GasDog GD300-NH3 and GD300-H2 fixed single gas detectors. These detectors are specially designed to continuously monitor NH3, H2, and other hazardous gases within the production environment.

The detectors were installed in key production areas and integrated with alarm controllers. The system transmits real-time gas concentration data via RS485 signals to the company’s internal safety monitoring network and also reports data to the national safety supervision platform, ensuring full regulatory compliance.

After thoroughly evaluating various suppliers and considering product performance, compatibility, and support, the company chose to partner with GasDog as their gas detection solution provider.

5. Monitoring Hydrogen Sulfide Gas with Online Fixed Detector

Background: The Bridgestone Group required a 24-hour monitoring solution for Hydrogen Sulfide (H2S) at their newly built sewage treatment plant. One of their key requirements was for personnel at an office located 800 meters away to be able to remotely view the real-time data from eight on-site monitoring points.

This continuous monitoring was essential for ensuring workplace safety and maintaining air quality standards in and around culverts and enclosed environments where H2S buildup poses serious health risks.

Solutions: Gas Dog recommended the online fixed H2S gas detector, equipped with a display, sound and light alarm, and paired it with a one-to-four-eight bus multifunctional color screen controller. This system supports centralized data display and management from up to eight monitoring points, viewable even from remote office locations.

Each fixed gas detector was further connected to two blowers in parallel via two independent relay outputs. When the H2S concentration exceeds safe levels, the system automatically activates the blowers, injecting fresh air into the culvert environment to mitigate the gas hazard.

As the customer had no prior experience with fixed gas detection systems or bus-type controllers, GasDog ensured a smooth installation process by:

- Pre-labeling all wiring connections for each GD300-H2S detector at the factory.

- Mapping each detector to its corresponding monitoring point before delivery.

This allowed the customer to perform simple on-site wiring and complete the installation quickly and accurately, without needing advanced technical expertise. The Bridgestone Group was highly satisfied with the ease of deployment and the effectiveness of the solution provided by GasDog.

6. Monitoring Waste Gas with GD300 Fixed Gas Detectors

Background: An environmental protection company in East China required a set of online gas detectors for monitoring and controlling emissions during the treatment of waste gas, which primarily contained Ammonia (NH3) and Hydrogen Sulfide (H2S). The company’s process involves collecting waste gas, treating it through a centralized system, and then discharging it into the atmosphere. Before discharge, it is critical to monitor the gas concentration post-treatment to ensure compliance with environmental standards.

Through further communication with the company representative, we learned that the detection point operates under slightly positive pressure, with stable humidity and ambient temperature. These conditions meant no pretreatment system was necessary. Instead, the system could directly connect an external pump to draw gas from the chimney into the probe’s air chamber for real-time monitoring.

Solutions: For this application, we recommend GD300 fixed series gas detectors, with a detection range of 0–100 ppm. To meet the monitoring requirements, one NH3 probe and one H2S probe were installed at the same monitoring point to independently track the concentration of each gas in the treated waste stream.

The company’s engineer found the proposed solution well-suited to their process and initially purchased two sets. After successful installation, they shared on-site photos with us and expressed satisfaction with the ease of integration and the performance of the devices.

Due to the positive experience, the company later purchased four additional batches of NH3 and H2S detectors, further showing their appreciation for GasDog’s product quality and service support.

7. Hydrogen Cyanide Detection in Gold Plating Tank Production Line

Background: A professional company specializing in the production of flexible printed circuit boards is recognized globally for its advanced process technology and high market share. On its gold plating tank production line, Potassium Cyanide is used as a raw material. This process poses a serious safety risk due to the potential release of Hydrogen Cyanide (HCN) — a highly toxic gas historically used as a chemical weapon during World War II.

To ensure workplace safety and prevent toxic gas exposure, the installation of a GD300-HCN fixed gas detector was deemed necessary. During project discussions, the customer’s engineer noted that even 316 stainless steel used on-site was susceptible to corrosion and requested a corrosion-resistant titanium alloy housing for the gas detector probe.

Solutions: While titanium alloy is highly resistant to corrosion, its cost was prohibitively high, with the price of the housing alone exceeding tens of thousands of RMB, not including the rest of the detector system. However, the customer’s acceptable budget for the entire unit is not enough, making the titanium solution unfeasible.

To find an alternative, we asked the customer which materials do not corrode in their working environment apart from titanium alloy. They responded that plastic materials are generally not prone to corrosion on-site.

Taking this into account, and to balance performance with cost, we proposed a solution using a nylon shell housing combined with high-performance HCN sensors. This setup provided the necessary corrosion resistance while remaining within the customer’s budget.

The customer approved the nylon housing solution and ultimately purchased 15 units of the GD300-HCN gas detector, expressing satisfaction with the cost-effective and tailored approach provided by GasDog.

8. Enhancing Food Preservation with GD200-N2 Gas Detector Technology

Background: An agricultural technology company specializing in the processing of fruits and nuts was concerned about the purity of nitrogen (N2) in their food packaging bags. To extend shelf life and prevent spoilage, nitrogen is used to displace Oxygen (O2), which promotes oxidation and decay. Even a small amount of residual Oxygen inside the packaging could lead to deterioration of the food product.

Manager Wang, responsible for packaging quality control, provided a sample image of their food packaging, which measured approximately 10 × 6 × 3 cm. Given the small size of the packaging and the strict requirement that no oxygen be present, they needed a precise and minimally invasive method to verify the N₂ concentration inside the sealed packaging.

Solution: After evaluating their requirements, we recommended the GD200-N2 portable pump-suction gas detector, specially modified for the food packaging environment. This model is ideal for detecting nitrogen concentration in small, sealed spaces without significantly disturbing the internal gas balance.

Key features of the customized solution include:

- Front air inlet/outlet equipped with fine needles to puncture the packaging gently. Low-flow air pump setting to draw just enough gas for accurate detection without depleting the bag’s internal atmosphere.

- The detector’s pump draws a small sample of gas from the packaging bag, analyzes it using the N2 sensor, and then returns the gas back into the packaging, maintaining internal pressure and composition as much as possible.

After explaining the detector’s working principle to Manager Wang, we received food packaging samples from their team the same day. GasDog technicians conducted the test immediately, recorded the process on video, and shared it with the customer. Manager Wang was highly satisfied with our response speed, service, and test quality, and proceeded to purchase the GD200-N2 detector that day.

9. Nitrogen Detection for Precision Engine Components

Background: A company specializing in the development and production of piston products for fuel engines used in various types of vehicles, with an impressive annual output of 50 to 60 million units, is recognized as a strong precision enterprise in the industry. It maintains long-term, friendly cooperation with many major power locomotive brands, demonstrating its solid reputation and capabilities.

Three years ago, driven by the needs of new product development and product quality inspection, the company approached GasDog in search of a portable Nitrogen (N2) detector. This was necessitated by the use of a Nitrogen generator in their new R&D line, which would continuously produce nitrogen for processes such as bottle filling, storage, processing, and utilization. One key requirement was to measure the purity of nitrogen inside Nitrogen bottles to evaluate the generator’s performance and efficiency.

Solution: Upon communication with the company’s technical lead, it was clarified that ultra-high precision was not required, and due to budget considerations, we recommended the cost-effective GD200 portable N2 detector, selecting the standard precision version to meet their needs.

After receiving the detector, the engineer found it somewhat challenging to operate initially. We stepped in with comprehensive after-sales support, explaining the proper setup and usage. The support team suggested purchasing a flow meter and a pressure-reducing valve, and advised to:

- Adjust the pressure to standard atmospheric pressure

- Set the flow rate at 1000 ml/min for accurate detection

- This flow rate is slightly higher than the detector’s built-in pump speed of 750 ml/min, ensuring optimal measurement performance.

Throughout the process, we remained committed to solving customer challenges, reinforcing our reputation for professional, reliable technical and after-sales support.

10. Advanced Oxygen Detection Solution for Complex Experimental Environments

Background: Mr. Zhang from the School of Environment of a certain university consulted our regarding the use of a portable Oxygen detector. He explained that the experimental environment is more complex than standard detection environments, with the presence of water vapor and dust. The experimental setup includes a container with a tube port, requiring the instrument to be equipped with a detection hose that can be extended into the container for gas sampling and collection.

Unlike the normal atmospheric oxygen concentration of 20.9% VOL, the theoretical oxygen concentration in the experiment is approximately 10% VOL. The alarm thresholds of the detector need to be adjusted accordingly to meet the specific experimental requirements. Due to the generation of significant water vapor and dust during the experiment, preliminary drying and filtering treatments are conducted to reduce interference.

Solution: After careful consideration, Mr. Zhang selected the GD200 portable pump-suction sampling Oxygen detector, which features a data storage function. This device supports hose-based sampling and is equipped with a filter nozzle to effectively block water vapor and dust particles.

The detection range is 0–25% VOL, meeting the expected concentration levels in the experimental environment. The use of a filter tip helps further purify the sampled gas, improving measurement accuracy and reducing potential sensor contamination. The packaging detector is operated within tolerance conditions to help prolong its service life.

11. Critical Oxygen Alarm Solutions for Industrial Safety

Background: In June 2014, a Nitrogen pipeline leak occurred in a factory, resulting in dozens of workers suffering from Hypoxia due to O2 deficiency. Many exhibited varying degrees of symptoms caused by low Oxygen levels. In response to this incident, the factory recognized the critical need to install Oxygen detection and alarm systems to ensure worker safety.

Solution: To address this need, we offer two Oxygen monitoring solutions:

- GD300-O2: A fixed O2 detector equipped with an independent probe, display, and built-in alarm. It provides real-time Oxygen concentration readings and immediate audible/visual alerts when levels fall below safety thresholds.

- Probe with Display (No Alarm): This version features a display probe without a built-in alarm. When O2 concentration drops below 19.5% VOL, the relay output is triggered to activate an external alarm light. The external alarm light is customizable and provided separately by the customer.

12. Safety and Monitoring with Fixed Ozone Probes in Cosmetics Production

Background: In late 2016, a renowned cosmetics company purchased our handheld Ozone (O3) detector to monitor Ozone levels during their disinfection processes. The device performed well and met their expectations. In July 2017, the company’s purification project team approached us with a new requirement: to install fixed O3 probes in the disinfection rooms on each floor of their facility for continuous and centralized monitoring.

Solution: To meet their needs, we first provided a trial setup consisting of one fixed Ozone probe. After a month of testing, the customer confirmed that the readings from the fixed probe aligned closely with those from the handheld detector. Satisfied with the results, they proceeded to purchase over 20 sets.

Each of the five floors was equipped with four fixed O3 gas detectors connected to a 4-channel host. The host collected data from the probes and transmitted it via RS485 signals. These signals were then converted and uploaded to a central computer using an adapter. This setup allowed the customer to monitor real-time O3 concentration data from all probes across the facility, ensuring consistent and effective disinfection management.

13. Ozone Detection for Pharmaceutical Cleanroom Sterilization

Background: A pharmaceutical factory in California requires separate sterilization of a Class 100 cleanroom. To achieve this, an Ozone generator is installed directly inside the room, with disinfection time set according to specific needs. The machine automatically shuts off after the cycle is complete.

To verify the disinfection process, the factory needs to monitor O3 concentration during operation to ensure it reaches approximately 20 ppm—the standard required for effective sterilization. Since personnel cannot be present during the disinfection process due to ozone toxicity, the factory sought a solution for remote concentration monitoring and post-process data analysis.

Solution: GasDog recommended the GD200-O3 single gas detector, configured for a 0–50 ppm measurement range with data storage and export capabilities. The instrument is placed inside the cleanroom during the disinfection cycle, with a customizable logging interval (e.g., one reading every 5 seconds). After the cycle, staff retrieve the detector and download the recorded data via USB, which can be analyzed in Excel and printed for record-keeping.

The GD200-O3 utilizes an internal sampling pump to actively draw gas into the sensor, ensuring fast response and high accuracy. This pump-suction design minimizes the risk of Ozone exposure to personnel and is particularly well-suited for monitoring toxic gases.

Customer feedback confirms that the GD200-O3 is sensitive, accurate, and meets the demanding requirements of a Class 100 pharmaceutical cleanroom environment.

14. SO2 Monitoring in Steel Desulfurization Process

Background: As a leading enterprise in the steel industry, the company enjoys a geographically advantageous location and strong governmental support. It is actively promoting the construction of a green industrial base with an annual production capacity of several million tons of stainless steel. Guided by principles of green development, high-quality production, cost efficiency, and intelligent manufacturing, the company aims to become a premium stainless steel sheet intelligent manufacturing service provider.

In the production process, Sulfur Dioxide (SO2) is known to be one of the major harmful gases emitted, primarily originating from the combustion of sulfur-containing substances. The engineering contractor, after receiving the client’s request, needed to install an online SO2 monitoring device at the desulfurization inlet of the hot blast furnace. The gas temperature can reach up to 200°C but is generally controlled to remain near room temperature. Therefore, there was no need for a full-scale CEMS (Continuous Emission Monitoring System). A cost-effective and simplified detection setup was preferred to meet monitoring needs while keeping expenses under control.

Solution: Upon receiving the client’s requirements, GasDog carefully considered the challenges of outdoor pipeline monitoring, including high temperatures and the presence of dust and impurities within the desulfurization ducts. To ensure stable and accurate SO2 detection, the GD300-SO2 fixed gas detector was recommended as the preferred solution.

This system is equipped with:

- 4-20mA analog output and RS485 digital signal

- Dual flowmeter design to control both positive and negative pressure gas flows, ensuring consistent and accurate monitoring data

- Flexible configuration options include solenoid valves, stainless steel filters, oil and dust removal components, dryers, and dehumidifiers to protect the sensor and extend its lifespan.

- A high-temperature sampling probe rated up to 600°C can reduce gas temperature and remove moisture to ensure precise readings.

The complete pre-treatment monitoring system is easy to install and operate — once fixed in place and powered on, it operates continuously with minimal maintenance requirements. Since the equipment functions 24/7, it is recommended to periodically replace filter elements in the filtration units to maintain long-term accuracy and reliability.