A gas detector is a device used to identify the presence and measure the concentration of gases in the surrounding environment. It employs specialized sensors to detect specific gases, such as Carbon Monoxide, Methane, and Hydrogen Sulfide. When gas levels reach potentially hazardous thresholds, the detector triggers alarms or alerts to ensure safety and enable timely responses.

Content

- 6 Types of Gas Detectors for Sale

- What Gas Types Can It Detect?

- How Does a Gas Detector Work?

- Advantages of GasDog Gas Detectors

- What are Gas Detectors Used for?

- Gas Detector Concentration Units

- Self Calibration and Zero Calibration

- FAQs about Gas Detector

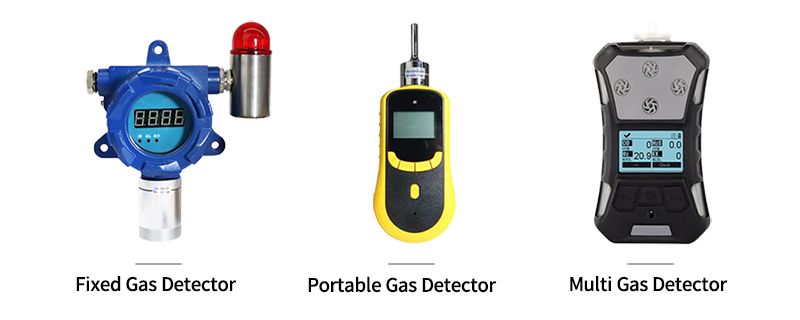

6 Types of Gas Detectors for Sale Online

Currently, GasDog.com provides industrial gas detector include portable gas detectors, fixed gas detectors, multiple gas detectors, combustible gas detectors, toxic gas detectors, and VOCs gas detectors:

Portable Gas Detector

The portable gas detector is small, lightweight, and easy to carry to different places. The instrument has the characteristics of high sensitivity and fast response and can detect gas leakage or concentration exceeding the standard in time. Most of them use LCD screen displays, which can visually display the concentration of detected gas. At the same time, it can also record and store data to facilitate subsequent data analysis.

Fixed Gas Detector

GasDog fixed gas detector is a gas monitoring device installed in a fixed location to continuously monitor changes in gas concentrations in the environment. The fixed gas detector is usually installed in factories, laboratories, tank farms, mines, etc., and can be connected by cable to a control room or monitoring system.

Multi-Gas Detector

Multi-gas detectors can simultaneously monitor many different types of gases, such as combustible gases, toxic gases and Oxygen. The common multi-gas detector is a 4-gas detector, which is used to detect combustible gases, Oxygen, Carbon Monoxide and Hydrogen Sulfide.

Toxic Gas Detector

The toxic and harmful gas detector is specially designed to detect the concentration of various toxic gases, which can monitor Carbon Monoxide, Ammonia, Hydrogen Sulfide, Hydrogen Cyanide, Formaldehyde, Ozone, Ethylene and other toxic gases. It can be used for real-time detection of petroleum, chemical, pharmaceutical, electric power, coal and other places where toxic and hazardous gases are present to ensure the safety of workers.

VOC Gas Detector

VOCs gas detector is a device designed to detect and measure the concentration of VOCs in the environment. VOCs are a class of compounds that can be volatilized from liquid or solid substances, including Formaldehyde, benzene, toluene and others. These compounds typically originate from industrial processes, vehicle emissions, construction materials, etc.

Combustible Gas Detector

Combustible and flammable gas detector is a device designed to detect and measure the concentration of combustible gases in the environment. It is commonly used in industrial, commercial and residential environments and can monitor a wide range of combustible gases, such as natural gas, Methane, Ethane, Propane, and others. Combustible gas detectors are highly sensitive and can detect very low concentrations of combustible gases.

What Gas Types Can It Detect?

- Combustible Gases: Ammonia (NH3), Hydrogen Sulfide (H2S), Methane (CH4), Methyl Bromide(CH3Br), Phosphine (PH3), Ethylene (C2H4), hydrogen (H2), etc.

- Toxic and Hazardous Gases: Ammonia (NH3), Carbon Monoxide (CO), Hydrogen Sulfide (H2S), Chlorine (Cl2), Hydrogen Chloride (HCL), Hydrogen Cyanide (HCN), Sulfur Dioxide (SO2), Phosphine (PH3), etc.

- Volatile Organic Compounds Gas Detection: Methane (CH4), Methyl Bromide (CH3Br), Formaldehyde (CH2O), Ethylene (C2H4), etc.

- Multi Gas Detection: 4 Gas: combustible gas (LEL), Oxygen (O2), Carbon Monoxide (CO), Hydrogen Sulfide (H2S). 5 Gas: combustible gas (LEL), Oxygen (O2), Carbon Monoxide (CO), Hydrogen Sulfide (H2S), volatile organic compounds (VOC).

How Does a Gas Detector Work?

Gas detectors operate based on various principles to detect and quantify the concentration of gases in the environment. Common sensing mechanisms include chemical reactions, semiconductor conductivity changes, infrared absorption, electrochemical reactions, and photoionization. These sensors interact with target gases, generating electric signals, color alterations, or current fluctuations, which are then converted into gas concentration measurements or alarm indications.

- Chemical sensors: Use a specific chemical reaction to detect a target gas. The sensor usually contains a layer of sensitive material that reacts with the target gas to produce an electrical signal or color change. For example, an Oxygen sensor may use a material such as aluminum oxide, and when Oxygen reacts with these materials, a change in resistance or current occurs.

- Semiconductor sensors: Semiconductor sensors are based on the fact that the resistance of a semiconductor material changes with the concentration of a gas. When a target gas is present, the conductivity of the semiconductor material changes to measure the gas concentration. This type of sensor is typically used to detect flammable gases such as Methane or Ethylene.

- Infrared absorption sensors: Certain gas molecules absorb light at specific infrared wavelengths. Infrared absorption sensors detect gas concentration by sending infrared light into a sample gas and measuring how much light is absorbed. This technique is commonly used to detect gases such as carbon dioxide and Methane.

- Electrochemical sensors: Use an electrochemical reaction to measure gas concentration. The sensor contains an electrochemical cell that triggers a redox reaction when the target gas enters the cell, resulting in a current or voltage signal.

- PID (Photoionisation detection) sensors: Use UV light to ionize gas molecules to produce electrons and ions. The intensity of the electron or ion stream required for the measurement is proportional to the gas concentration. Typically used to detect volatile organic compounds (VOCs).

These sensing principles allow the gas detector to quickly and accurately identify the concentration of hazardous gas and alert the user with an alarm or display.

Advantages of Gas Dog Gas Detectors

GasDog detectors offer several advantages, especially in environments where the presence of hazardous gases poses a potential risk to human health and safety. Some of the key advantages of gas detectors include:

- Designed to be simple and easy to use, it is equipped with an intuitive interface and operation mode, enabling users to quickly get started and understand the data.

- The gas detector provides real-time monitoring, instantly displaying the current gas concentration, helping the user to understand the safety of the environment at any time. Explosion-proof multi-gas detectors are also capable of detecting many different types of gases at the same time, making them suitable for a wide range of working environments and hazardous situations.

- Gas Dog gas detector adopts high sensitivity and high stability electrochemical sensor, with an on-site sound and light alarm function, when the gas concentration exceeds the standard value, the detector will immediately send out an alarm, to protect the workers in the hazardous site operation.

- The portable gas detector is small in size, easy to carry, good quality and low price. In addition, the gas detector also adopts waterproof, dustproof and explosion-proof design, with good corrosion resistance and durability.

- Gas detectors also have data storage and recording functions, which allow you to view historical data on the instrument, record changes in gas concentration over time, and provide data analysis.

- For hazardous environments, some gas detectors also have an explosion-proof design to ensure safe operation even in flammable and explosive locations.

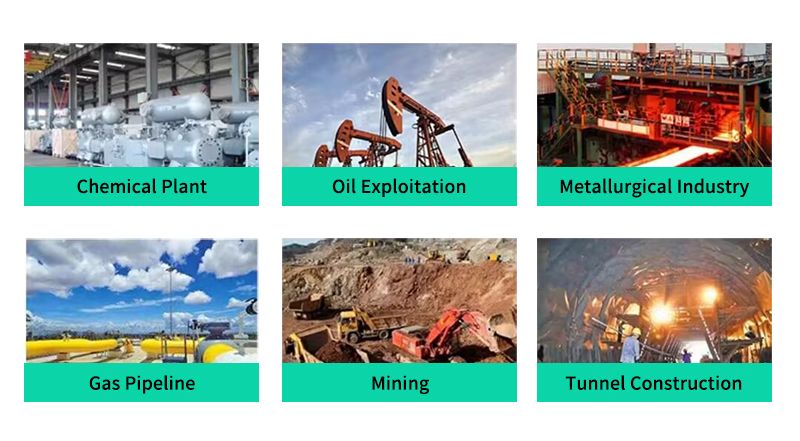

What are Gas Detectors Used for?

- Industrial places: Chemical plants, petrochemical plants, mines, dangerous goods warehouses, etc., used to detect the leakage of toxic gases, combustible gases and other dangerous gases.

- Building places: Parking lots, basements, tunnels, etc., for detecting the concentration of Carbon Monoxide, carbon dioxide and other harmful gases.

- Family places: Kitchens, bathrooms, etc., for detecting the leakage of gas, natural gas and other flammable gases.

- Medical places: Operating rooms, wards, etc., for detecting the concentration of Oxygen, Nitrogen and other gases.

- Laboratories: Chemical laboratories, biological laboratories, etc., for the detection of toxic gases, flammable gases and other leaks.

- Public places: Subway stations, airports, shopping malls, etc., are used to detect the concentration of toxic gases, smoke, etc., to protect public safety.

Gas Detector Concentration Units

Gas detectors are devices used to measure the concentration of various gases in the air to ensure safety and monitor potential hazards. The measurement units used by gas detectors depend on the type of gas being detected and the region's standards. Here are some common measurement units for specific gases:

| Gas Types | Units |

| Toxic Gases | Parts per million (ppm): This unit measures the concentration of a gas in the air as a ratio of the gas molecules to the total air molecules. It is commonly used for toxic gases such as Carbon Monoxide (CO), Hydrogen Sulfide (H2S), and Ammonia (NH3). |

| Flammable Gases | Lower Explosive Limit (LEL) or Lower Flammable Limit (LFL): Expressed as a percentage, this unit indicates the minimum concentration of flammable gas in the air that can potentially ignite or explode. It is often used for gases like Methane (CH4) and Propane (C3H8). |

| Oxygen (O2) | Percentage (%): This unit represents the volume percentage of Oxygen in the air. Normal ambient air typically contains around 20.9% Oxygen. |

| Combustible Gases | LEL or LFL: As mentioned above, this unit is used for gases that can catch fire or explode when mixed with air within a specific concentration range. |

| Volatile Organic Compounds (VOCs) | Parts per billion (ppb): This unit measures very low concentrations of VOCs, which are commonly found in indoor environments and industrial settings. |

| Carbon Dioxide (CO2) |

Percentage (%) or parts per million (ppm): CO2 concentration is often measured in percentage volume for high levels (e.g., in confined spaces) and in ppm for ambient air quality monitoring. |

| Other Gases | Various units can be used depending on the gas, such as milligrams per cubic meter (mg/m³), micrograms per cubic meter (µg/m³), or simply percentage (%). |

It's important to note that standards and regulations might vary based on geographical location and industry. Gas detectors are typically calibrated to specific units and ranges based on the target gas. Users should always refer to the manufacturer's instructions and local regulations for accurate interpretation of gas detector readings.

Self Calibration and Zero Calibration

Self Zero Calibration: Gas detector self-calibration is a feature in some advanced gas detection systems that enables the device to automatically adjust its sensor readings without manual intervention. Using internal algorithms and reference sensors, the gas detector periodically assesses its own accuracy and makes necessary adjustments to maintain reliable measurements. This self-calibration helps ensure continuous accuracy, reduces downtime, and minimizes the need for external calibration procedures.

Zero Calibration: It is a critical calibration process for gas detectors that establishes the baseline reading of the sensor in the absence or near absence of the target gas. During zero calibration, the gas detector is placed in a clean environment free from the gas it is designed to detect. The sensor should ideally read close to zero in this environment. If any deviation occurs, the detector is adjusted to ensure its baseline reading accurately reflects the absence of the target gas. Zero calibration ensures accurate measurements by compensating for sensor drift and environmental factors.

FAQs about Gas Detector

Q1: Do gas detectors require maintenance?

A1: Yes, regular maintenance is essential. Cleaning sensors, replacing parts as needed, and adhering to manufacturer guidelines for calibration and sensor replacement help maintain accurate and reliable performance.

Q2: What is a gas alarm or alarm threshold?

A2: Gas detectors have preset alarm thresholds. When gas concentrations exceed these thresholds, the detector triggers alarms, such as visual and audible alerts, to warn individuals of potential hazards.

Q3: Can gas detectors be used in different environments?

A3: Yes, gas detectors are used in various environments, including industrial workplaces, commercial buildings, homes, laboratories, and outdoor areas, depending on the specific gas hazards present.

Q4: Can gas detectors detect multiple gases simultaneously?

A4: Some advanced multi gas detectors are capable of detecting multiple gases simultaneously using either separate sensors or multi-gas sensor arrays.

Q5: What should I do if my gas detector alarms?

A5: If your gas detector alarms, follow safety procedures, evacuate the area if necessary, and address the cause of the alarm. Seek guidance from your organization's safety protocols or local authorities.

In conclusion, a gas detector stands as an essential safeguard against potential airborne hazards, ensuring the safety of individuals in a wide range of environments. By diligently monitoring and accurately measuring gas concentrations, these devices play a pivotal role in preventing accidents, enabling timely responses, and maintaining secure working and living conditions. As technology advances, gas detectors continue to evolve, becoming increasingly sophisticated and adaptable, while their critical role in maintaining a secure and healthy atmosphere remains unwavering.